It’s an fascinating time for production industry experts, but your journey with AI commences with trusted custom machining services and products.

After you're all set to go, the next stage should be to identify your use instances. These are definitely the precise problems or opportunities where you Feel AI may help.Remember, AI is not a silver bullet which will address your complications. It is a Device that's good at some things, like getting designs in information, making predictions, and optimizing processes.

This standard of precision is essential in industries like aerospace, automotive, and health care, the place even the slightest deviation might have considerable implications.

Find out how evolving tariffs in 2025 will effects the global import and export of CNC machines and parts. Learn essential trade shifts, cost implications, And the way U.S. CNC outlets can adapt to transforming tariff guidelines.

CKA series automatic cnc lathe is 2 axis cnc lathe procedures of cutting for all sorts of shaft parts. This machine could procedure distinctive interior bore, ex-circle, round conical surface and screw thread, especially suitable for the small and middle sized shaft and plate operate piece from rough processing to finish processing in batch.

With this actual time info, the machines can be altered right away so that they are operating at peak functionality.

The opportunity to immediately adapt to different production demands has started to become more and more essential. AI improves CNC machining’s overall flexibility by enabling immediate changes to production parameters. This book investigates the numerous time reduction in reconfiguring machinery for various goods and the key roles AI-driven systems Enjoy Within this endeavor.

MultiCam CNC Waterjet: Having difficulties with budget or space constraints? MultiCam contains a waterjet Alternative to suit your needs! From small retailers to large businesses, MultiCam's numerous collection of CNC machines is tailor-made to suit all budgets and Tastes.

You won't have any anxieties about accuracy either as Just about every machine comes Outfitted with Licensed laser calibration technology and large metal Read frames that ensure sturdiness and security while cutting.

After the proposed ANN-ITWP system were proven, nine experimental tests cuts have been performed to evaluate the general performance on the system. From your test success, it had been evident the system could predict the tool put on online with a median error of ±0.037 mm. Experiments have revealed the ANN-ITWP system is able to detect Resource wear in three-insert milling operations online, approaching a true-time foundation.

What role does AI play in modern CNC milling? AI performs a pivotal job in predictive routine maintenance, examining wide quantities of operational knowledge to foresee likely element failures, Hence lowering downtime and extending machine lifespan.

The planet of manufacturing has witnessed a paradigm change with the appearance of Computer system Numerical Control (CNC) machines. These machines, specifically CNC milling machines, have revolutionized how we make intricate parts and components.

Once you've determined your use circumstances, it is time to pilot and iterate. This suggests starting small, testing your AI Resolution, Discovering from the results, and iterating depending on Whatever you've figured out.A great way To achieve this should be to Adhere to the lean startup methodology. This is a method of developing businesses and goods, which aims to shorten solution progress cycles and rapidly uncover if a proposed enterprise model is viable.

The future will probably be about exploring this technology and harnessing the strength of AI and machine learning to revolutionize CNC machining endeavours. Human involvement in machining procedures stays critical as we outline and refine AI parameters to optimize processes and redefine machining quality.

Neve Campbell Then & Now!

Neve Campbell Then & Now! Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Judge Reinhold Then & Now!

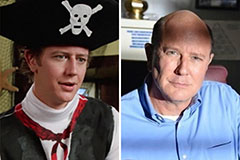

Judge Reinhold Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!